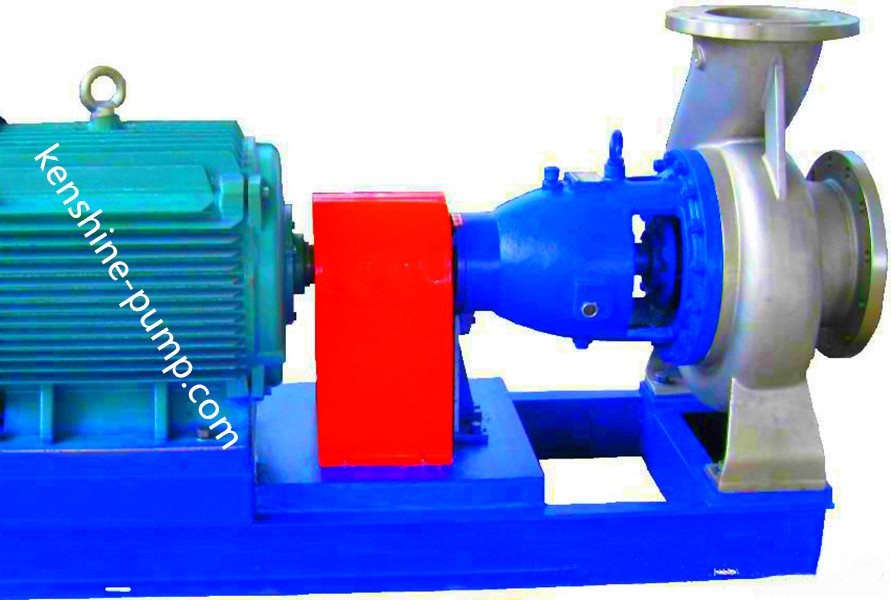

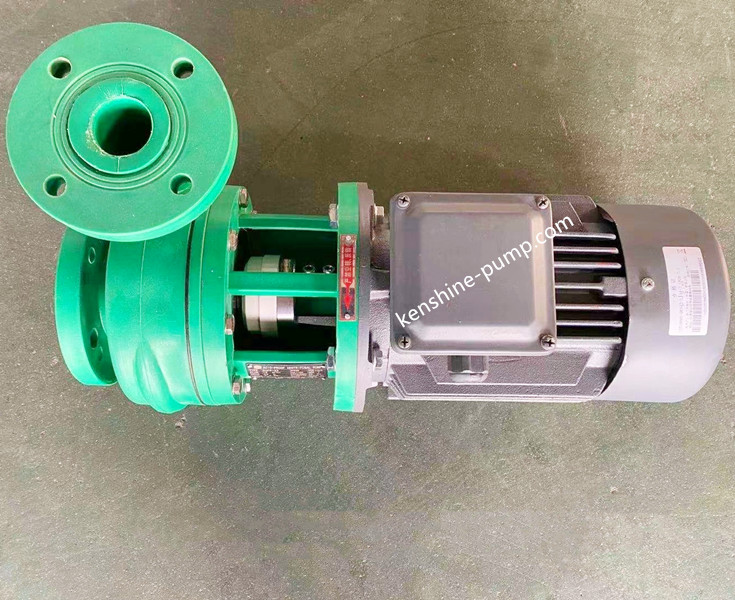

PBG Vertical Pipeline canned pump

- Model Number: PBG50-200

- Place of Origin: Jiangsu, China

- Minimum Order Quantity: 1 Pieces

- Supply Capacity: 600 Pieces/month

- MemberShip: Free Member

- Inquiry Now

pbg vertical pipeline canned pump Description

Product Name: pbg vertical pipeline canned pump

PBG shielded pumps can transport liquids that are harmful to human health, the environment, and equipment, as well as expensive and prone to leakage, due to their ability to ensure complete leak free operation.

2. It does not inhale air and is suitable for vacuum systems and conveying liquids that deteriorate when in contact with air.

3. No oil seal design, able to reliably transport liquids with high temperature, high pressure, low temperature, and large temperature and pressure changes that are difficult for general pumps to transport.

4. Bearings use the conveyed liquid for self lubrication, without the need for lubricating oil, so they do not contaminate the conveyed liquid and eliminate the trouble of regular oil injection.

5. The pump structure is reasonable, with the motor and pump coaxial, small size, light weight, small footprint, smooth operation, easy installation, no need for adjustment, and convenient maintenance.

6. The impeller adopts advanced hydraulic models, which have the characteristics of high efficiency and good performance.

7. The motor has no cooling fan, so the operating noise and vibration are very small.

8. The specification design of the pump inlet and outlet flanges is the same as that of standard valves, and they are located on the same centerline with a low center, which is convenient for pipeline layout. The pump room design is also more reasonable and practical.

9. The standardization and serialization of components are high.

10. The motor and junction box both adopt waterproof and explosion-proof structures, which can be safely used outdoors.

11. The pump can be operated in series or parallel according to the requirements of flow rate and head.

The newly adopted graphite bearings have the advantages of high wear resistance, low friction coefficient, anti-aging, and resistance to sediment and sand.

13. The top of the motor is equipped with an automatic exhaust valve. When the water pump is in use, simply open the inlet valve and release the air nozzle next to the exhaust valve. The air inside the pump body and motor will be automatically discharged from the automatic exhaust valve on the top of the motor. After exhaust, it will automatically close immediately, preventing the medium from flowing out of the pump, ensuring the normal operation of the water pump. Moreover, if air enters the pipeline during use, it can automatically discharge it. This function eliminates the need for a dedicated person to frequently open the valve for exhaust, greatly reducing the cost and manpower of regular use.

14. The unique detachable structure allows the pump to be used and maintained normally, such as removing scale and checking the wear of graphite bearings. Simply remove the connecting screw between the motor housing and the lower end cover of the motor, and push out the motor and predetermined components in the screw hole of the motor housing. Therefore, maintenance and regular inspection are extremely convenient.

15. Fully protected electrical control box: (this item is an optional component), equipped with pre embedded thermal protectors, water shortage probes, and water leakage probes inside the motor, can provide comprehensive protection for shielding the motor.

Canned pump is widely used in the petroleum and chemical industries, pharmaceuticals, textiles, nuclear power, military and urban water supply and drainage, fire boosting, high-rise building boosting water supply, garden sprinkler irrigation, HVAC refrigeration, and other cold and warm water circulation boosting. Especially in places with high requirements for vibration and noise, such as key projects, pump rooms, central air conditioning, etc. It can also be used to transport liquids that do not crystallize or solidify under pressure and temperature, especially liquids that are harmful and unsafe to human health and the environment, as well as valuable liquids such as highly corrosive, toxic, volatile, radioactive and other media.

2. It does not inhale air and is suitable for vacuum systems and conveying liquids that deteriorate when in contact with air.

3. No oil seal design, able to reliably transport liquids with high temperature, high pressure, low temperature, and large temperature and pressure changes that are difficult for general pumps to transport.

4. Bearings use the conveyed liquid for self lubrication, without the need for lubricating oil, so they do not contaminate the conveyed liquid and eliminate the trouble of regular oil injection.

5. The pump structure is reasonable, with the motor and pump coaxial, small size, light weight, small footprint, smooth operation, easy installation, no need for adjustment, and convenient maintenance.

6. The impeller adopts advanced hydraulic models, which have the characteristics of high efficiency and good performance.

7. The motor has no cooling fan, so the operating noise and vibration are very small.

8. The specification design of the pump inlet and outlet flanges is the same as that of standard valves, and they are located on the same centerline with a low center, which is convenient for pipeline layout. The pump room design is also more reasonable and practical.

9. The standardization and serialization of components are high.

10. The motor and junction box both adopt waterproof and explosion-proof structures, which can be safely used outdoors.

11. The pump can be operated in series or parallel according to the requirements of flow rate and head.

The newly adopted graphite bearings have the advantages of high wear resistance, low friction coefficient, anti-aging, and resistance to sediment and sand.

13. The top of the motor is equipped with an automatic exhaust valve. When the water pump is in use, simply open the inlet valve and release the air nozzle next to the exhaust valve. The air inside the pump body and motor will be automatically discharged from the automatic exhaust valve on the top of the motor. After exhaust, it will automatically close immediately, preventing the medium from flowing out of the pump, ensuring the normal operation of the water pump. Moreover, if air enters the pipeline during use, it can automatically discharge it. This function eliminates the need for a dedicated person to frequently open the valve for exhaust, greatly reducing the cost and manpower of regular use.

14. The unique detachable structure allows the pump to be used and maintained normally, such as removing scale and checking the wear of graphite bearings. Simply remove the connecting screw between the motor housing and the lower end cover of the motor, and push out the motor and predetermined components in the screw hole of the motor housing. Therefore, maintenance and regular inspection are extremely convenient.

15. Fully protected electrical control box: (this item is an optional component), equipped with pre embedded thermal protectors, water shortage probes, and water leakage probes inside the motor, can provide comprehensive protection for shielding the motor.

Canned pump is widely used in the petroleum and chemical industries, pharmaceuticals, textiles, nuclear power, military and urban water supply and drainage, fire boosting, high-rise building boosting water supply, garden sprinkler irrigation, HVAC refrigeration, and other cold and warm water circulation boosting. Especially in places with high requirements for vibration and noise, such as key projects, pump rooms, central air conditioning, etc. It can also be used to transport liquids that do not crystallize or solidify under pressure and temperature, especially liquids that are harmful and unsafe to human health and the environment, as well as valuable liquids such as highly corrosive, toxic, volatile, radioactive and other media.

Product Tags:Canned pump,shielded pump,centrifugal transfer pump,