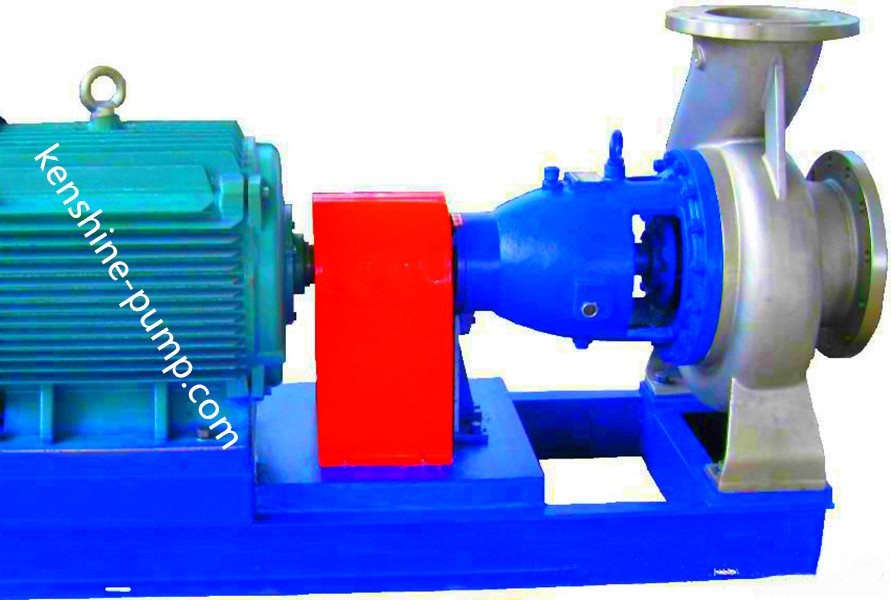

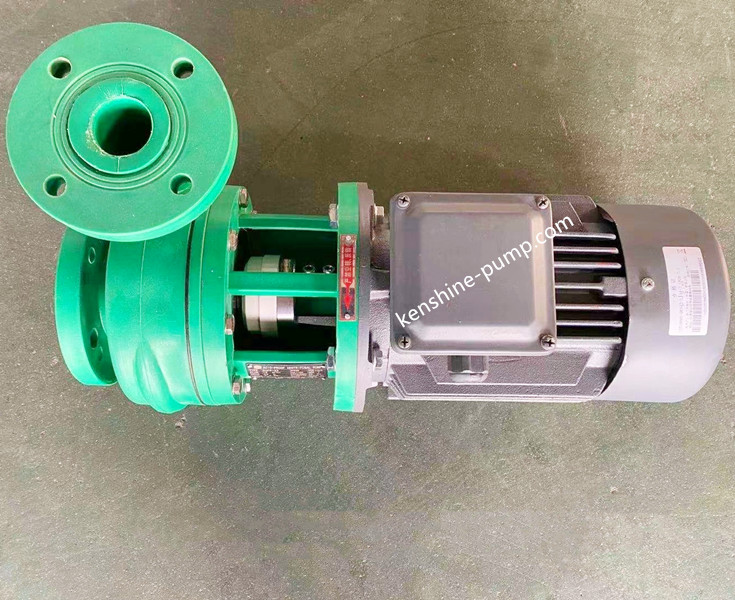

CZ Stainless steel chemical process pump

- Model Number: CZ65-250

- Place of Origin: Jiangsu, China

- Minimum Order Quantity: 1 Pieces

- Supply Capacity: 600 Pieces/month

- MemberShip: Free Member

- Inquiry Now

cz stainless steel chemical process pump Description

Product Name: cz stainless steel chemical process pump

CZ chemical process pump is suitable to transfer media being low-temperature or high-temperature, neutral or corrosive, being clean or containing solid grains, or being poisonous, inflammable or explosive. Itříđ™ mainly applied in such industries as chemical engineering, petrochemicals, steel works, power plants, papermaking, pulp, medicine, food and sugar refining.

Structural Features

Pump body: adopting foot supporting structure;

Impeller: closed, semi-open and full-open types; CZ series pumpříđ™ axial force is mainly balanced by the back blade or balance hole while the residual axial force is born by the bearing.

Pump cover: it works with the sealing gland to form a sealing cavity and the standard cavity dimensions can be provided with various seal types.

Shaft seal: according to different working conditions, such seal types can be adopted as packing seal, single end face mechanical seal, double end face mechanical seal, and mechanical seal in series.

Bearings:it adopts the thin oil lubrication mode and the oil level is controlled by a constant level oil cup,that fully ensuring the bearings working in a good lubrication state.

Shaft: Itříđ™ protected by a bushing to prevent the medium from contacting the shaft directly to improve the shaftříđ™ service life.

Working conditions

Medium temperature: -40 DegC to 260 DegC

Up to 400 DegC when taking special measures:

Flow Q=2~2400m3/h,Head:3-200(m)

Working pressure is up to 25bar

Rotation speed n=1450~3600 r/min,50Hz/60Hz

Pumpříđ™ rotation direction: clockwise when viewed from the motor to the pump.

Structural Features

Pump body: adopting foot supporting structure;

Impeller: closed, semi-open and full-open types; CZ series pumpříđ™ axial force is mainly balanced by the back blade or balance hole while the residual axial force is born by the bearing.

Pump cover: it works with the sealing gland to form a sealing cavity and the standard cavity dimensions can be provided with various seal types.

Shaft seal: according to different working conditions, such seal types can be adopted as packing seal, single end face mechanical seal, double end face mechanical seal, and mechanical seal in series.

Bearings:it adopts the thin oil lubrication mode and the oil level is controlled by a constant level oil cup,that fully ensuring the bearings working in a good lubrication state.

Shaft: Itříđ™ protected by a bushing to prevent the medium from contacting the shaft directly to improve the shaftříđ™ service life.

Working conditions

Medium temperature: -40 DegC to 260 DegC

Up to 400 DegC when taking special measures:

Flow Q=2~2400m3/h,Head:3-200(m)

Working pressure is up to 25bar

Rotation speed n=1450~3600 r/min,50Hz/60Hz

Pumpříđ™ rotation direction: clockwise when viewed from the motor to the pump.

Product Tags:chemical process pump,centrifugal pump,industrial pump,